For heavy-duty mechanical anchoring into concrete, CMU or masonry, builders generally choose between screw anchors or wedge anchors. Both can handle high loads, require predrilling, and are available in corrosion-resistant finishes for either interior or exterior use. However, there are some key differences to compare and consider.

Advantages of screw anchors versus wedge anchors

Wedge anchors, including expansion anchors, can be a good, low-cost option for many interior and exterior applications, but require multiple steps and tools to install. In contrast, the Titen HD heavy-duty screw anchor can be installed up to five times faster using an impact driver or impact wrench. A screw anchor allows for a closer minimum edge distance than a wedge anchor, which is optimal for sill plate work. But the most notable difference may be that the Titen HD is fully removable.

“In addition to permanent installation, Titen HD is a smart, practical solution for temporary anchoring jobs, like racking,” said Andrew Brigham, Group Product Manager at Simpson Strong-Tie. “Instead of grinding down abandoned wedge anchor heads at the old location, construction crews simply unscrew the Titen HD, then reposition the racking. This can save a lot of time and effort on the job.”

After determining that a screw anchor meets load and other engineering requirements, specifiers can begin to narrow down the available options. Designed for static, wind, and seismic areas, Titen HD heavy-duty screw anchors are code listed for cracked and uncracked concrete, as well as uncracked masonry. They come in a range of sizes and head styles, such as hex-head, plus washer-head and countersunk for low-profile installation. Corrosion resistance also factors into product design and selection, so Titen HD is made in three different varieties — zinc plated, mechanically galvanized, and stainless steel.

Titen HD® heavy-duty screw anchor

Titen HD has a zinc-plated finish. It’s made for dry, interior areas in non-corrosive environments. Common applications include sill plates, racking, heavy equipment, or tilt-wall anchoring. Titen HD also can be used for temporary, outdoor anchoring jobs, such as formwork or bracing.

Titen HD® mechanically galvanized heavy-duty screw anchor

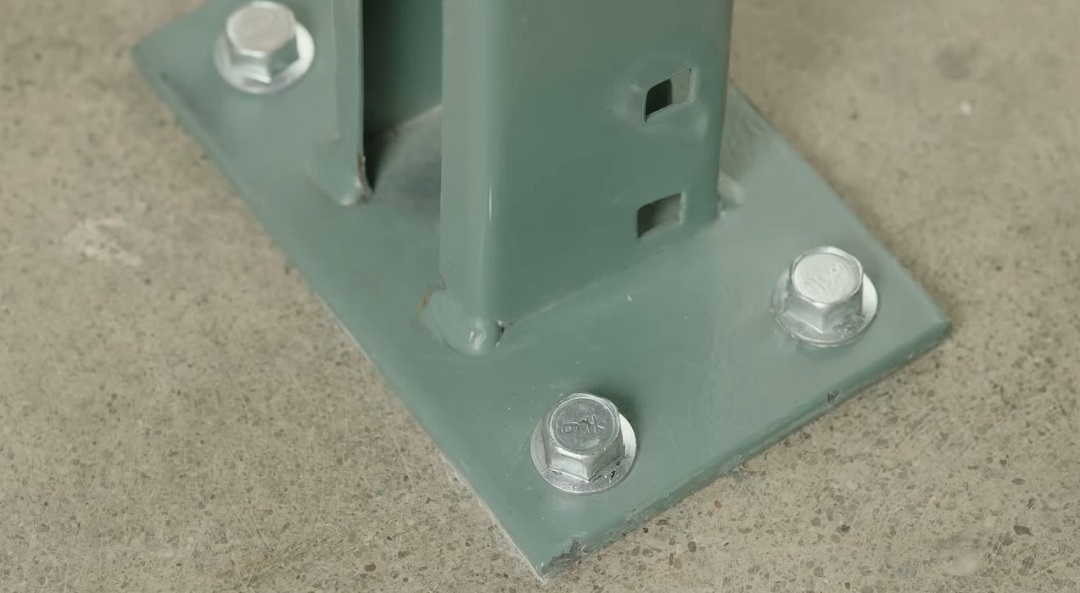

Titen HD mechanically galvanized has a corrosion-resistant finish designed for exterior use — as well as interior — in areas that are dry or damp. Common applications for this screw anchor include treated sill plates, ledgers, post bases and seating.

Stainless-steel Titen HD® heavy-duty screw anchor

Stainless-steel Titen HD is the right choice for outdoor anchoring in harsh weather conditions or environments where saltwater, chemicals or corrosive solutions may be present. It’s ideal for ledger connections, marine and port restoration, stadium seating, balconies, outdoor railing and other applications.

Two grades of stainless steel are available. Type 316 has the highest level of corrosion resistance for coastal areas exposed to saltwater. Type 304 is suitable for humid, moist and wet conditions near freshwater lakes or other environments. Whether Type 316 or Type 304 is being installed, stainless-steel Titen HD screw anchors should be used with stainless-steel connectors or other Simpson Strong-Tie connectors that feature corrosion-resistant finishes.

Anchoring requirements can vary for similar applications

Based on the presence of seismic activity or high-wind events, anchoring requirements can vary from one area of the country to another. Sometimes, a different screw anchor may be specified for the same application in a different geographic area. To plan accordingly, it’s essential to know and follow local anchoring requirements.

Strength and versatility for mechanical anchoring jobs

Across the construction industry, there are numerous alternatives for heavy-duty anchoring into concrete, CMU or masonry. Wedge anchors can be a viable option for many applications. But many builders are switching to the Simpson Strong-Tie® Titen HD® heavy-duty screw anchor. Compared to a wedge anchor, Titen HD is simpler and faster to install, provides a closer edge distance and is fully removable. Code listed for cracked and uncracked concrete, as well as uncracked masonry, Titen HD has become the clear choice for many heavy-duty, interior and exterior anchoring applications.

To learn more about Titen HD heavy-duty screw anchors, and explore free Anchor Designer™ software, visit our website.