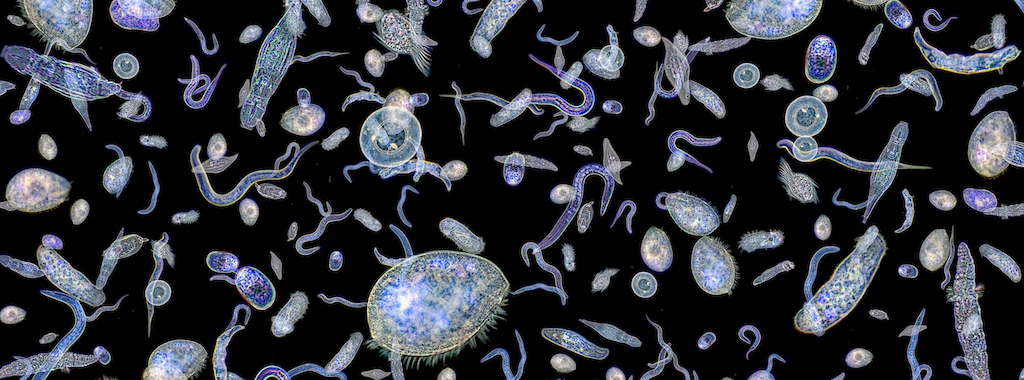

Legions of catatonic organisms lie asleep in the matrix, waiting only for momentary exposure to water and oxygen in order to awaken — whereupon the organisms immediately germinate, grow and fulfill their destiny, sealing the cracks in the fabric of their universe before falling dormant once again.

Continue reading “It’s Alive! Self-Healing Concrete, Materials Science and Other Evolutionary Developments”

Author: The Strong-Tie Blog Team

BIM Inception: The Construction Language of the Future

Robots. Drones. 3D printing. Self-driving bulldozers. If residential construction is ripe for so-called disruption (and sweeping advancements already made by commercial and industrial builders says it is), then most technologists, forward-thinkers and first adopters agree we’ll need a native, digital, data-based language to help run it all. Continue reading “BIM Inception: The Construction Language of the Future”

Happy Independence Day 2018

Thank you for stopping by! We’re taking a brief break today so Simpson Strong-Tie team members can celebrate the Fourth of July with family and friends.

Continue reading “Happy Independence Day 2018”

Little Locales Using Big Data to Prevent Bridge Failures

Situated on the northwest coast of Oregon, the resort town of Seaside — population 6,685 — seems an unlikely place for advanced seismic and tsunami simulations. But just offshore Seaside’s charming 1920s boardwalk and its broad, sandy beaches famed for razor clamming, the Juan de Fuca tectonic plate is slowly sliding underneath the behemoth North American plate.

Continue reading “Little Locales Using Big Data to Prevent Bridge Failures”

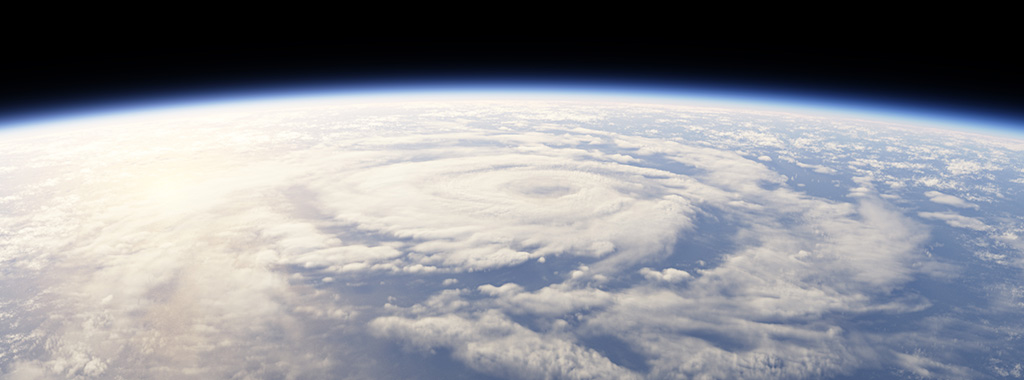

Hurricane Season: Understanding High-Wind Home Preparation

As we’ve seen with the hurricane seasons of that past decade or so, homes are not always built to withstand a major storm. The hurricane season of 2017 was one of the deadliest and costliest seasons in US history. Countless homes and buildings were severely damaged or destroyed, leaving thousands of families displaced. It will take years for communities to rebuild and recover from such devastation.

Fortunately, there are solutions that can help protect your home from a hurricane or high-wind event.

Continue reading “Hurricane Season: Understanding High-Wind Home Preparation”

Timber Strong Provides Real-World Engineering Experience

For the last three years, Simpson Strong-Tie has sponsored events at the Pacific Southwest Conference, a three-day competition promoted by the American Society of Civil Engineers for civil engineering students. This year, 18 universities from Southern California, Nevada, Arizona and Hawaii sent teams to Tempe, Arizona, for the competition, which was co-hosted April 12–14 by Arizona State and Northern Arizona Universities.

The students compete in numerous events over the three days, with the two main events being Concrete Canoe and Steel Bridge builds sponsored by American Concrete Institute and American Institute of Steel Construction respectively. In the previous two years, Simpson sponsored Simpson Jeopardy and Timber Towers / Giant Jenga, but this year we were excited to sponsor the inaugural Timber Strong Design Build competition.

Continue reading “Timber Strong Provides Real-World Engineering Experience”

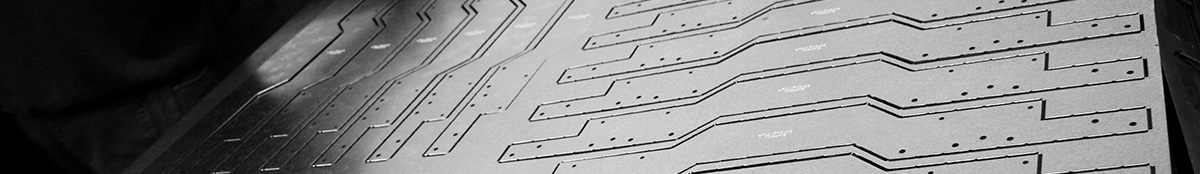

Carbon-Fiber-Reinforced Polymer: Exploring Industrial Applications

The fact that carbon-fiber-reinforced polymer (CFRP) is strong enough to replace bulkier strengthening materials can be a surprise even to some experienced commercial contractors. After all, carbon fibers are only 5 to 10 microns in diameter, a little wider than spider silk.

Intuitively, it doesn’t seem that these tiny fibers could be a major component of a concrete strengthening system several times stronger than mounted steel plates.

Continue reading “Carbon-Fiber-Reinforced Polymer: Exploring Industrial Applications”

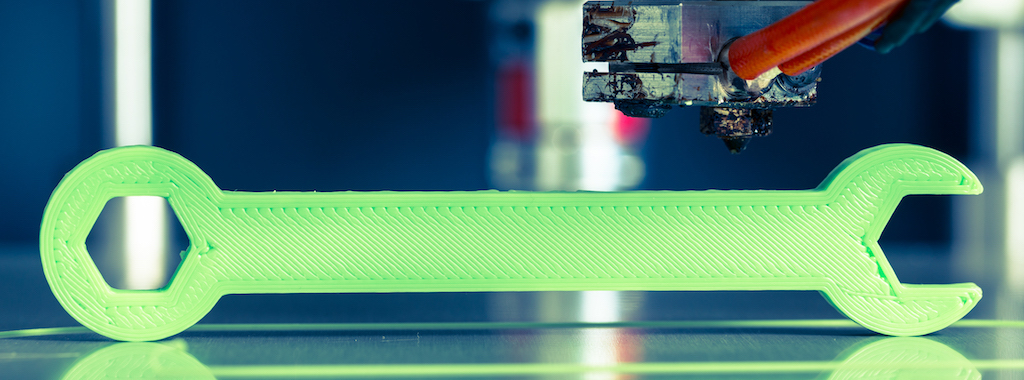

3D Printing and Its Impact on the Building and Construction Industry

Whether you call it 3D printing, additive manufacturing or contour crafting, the ability to create something — from a small tabletop model to a livable home or towering skyscraper, to list just a few possibilities — out of paper-thin materials is intriguing, and promises to shape the future of our world. So promising is this recent technology, in fact, that manufacturing industries, government entities and educational institutions have made significant investments in 3D-printing technologies. These ventures, particularly those driven by partnerships, are shaping up to have a big impact on the building and construction industry.

Continue reading “3D Printing and Its Impact on the Building and Construction Industry”

News from IBS & WOC — What You Missed at the 2018 Simpson Strong-Tie Exhibit Booths

It was a muggy Tuesday morning, and thousands of people from all over the world were heading toward the long bank of doors to the Orlando Convention Center. The broad stream of people was just one of the signs that the International Builders’ Show® was underway.

Inside Hall C The Simpson Strong-Tie booth was impressive with a festively lit Outdoor Accents® pergola and shelves of Simpson hats and tee-shirts to give to booth visitors.

Continue reading “News from IBS & WOC — What You Missed at the 2018 Simpson Strong-Tie Exhibit Booths”

Simpson Strong-Tie Renews Partnership with Habitat for Humanity to Help Build More Disaster-Resilient Homes

Simpson Strong-Tie is renewing its partnership with Habitat for Humanity to continue supporting the housing organization’s efforts to make homes resilient to disasters. This is the 12th consecutive year of the partnership to help more families in need of a decent and affordable place to call home. To date, the manufacturer of structural product solutions has contributed more than $2.75 million toward Habitat’s mission.

Continue reading “Simpson Strong-Tie Renews Partnership with Habitat for Humanity to Help Build More Disaster-Resilient Homes”