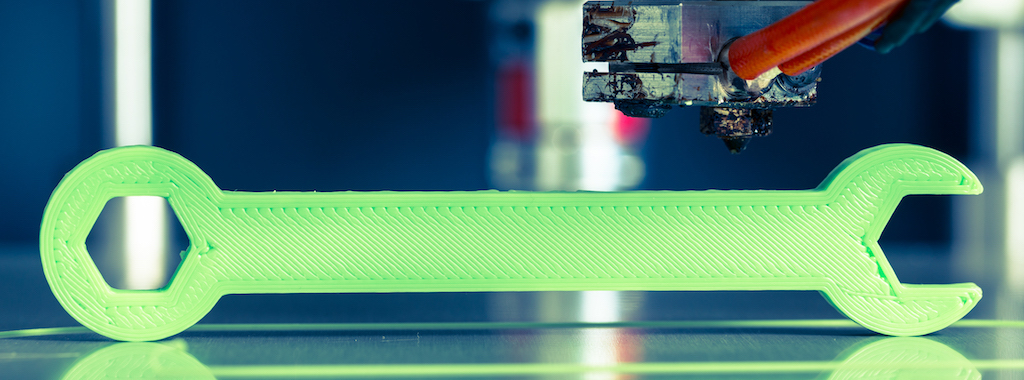

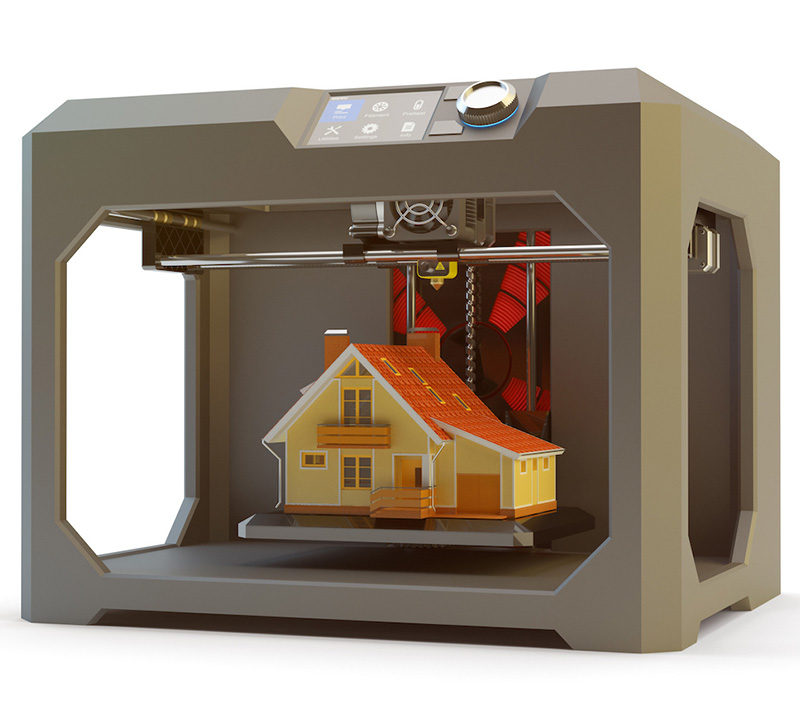

Whether you call it 3D printing, additive manufacturing or contour crafting, the ability to create something — from a small tabletop model to a livable home or towering skyscraper, to list just a few possibilities — out of paper-thin materials is intriguing, and promises to shape the future of our world. So promising is this recent technology, in fact, that manufacturing industries, government entities and educational institutions have made significant investments in 3D-printing technologies. These ventures, particularly those driven by partnerships, are shaping up to have a big impact on the building and construction industry.

A History of 3D Printing

3D-printing technology may seem new to most, but the basis has been around since 1981. Hideo Kodama of Nagoya Municipal Industrial Research Institute in Japan is recognized as the first to person to publish his account of a functional rapid prototyping system using photopolymers placed layer upon layer to make a larger object. A few years later in 1984, Charles Hull invented stereolithography, enabling designers to make 3D models using digital data. By the 1990s and early 2000s, researchers had begun exploring the usage of 3D printed materials in medicine and manufacturing, including a 3D printer that could produce and build other 3D printers. Today, 3D printers are much more common and affordable than ever before, and machines can now print using all sorts of materials like glass, concrete and much more.

3D Printing and the Construction Industry

When it comes to the construction industry, there are some obvious reasons why 3D printing is a huge innovation as a technology that can reduce costs across the board in time, materials and labor. Among other uses, 3D printers can be deployed to quickly create housing in disaster areas, create modular and prefab homes in far less time, reduce construction site waste, and potentially even help build colonies on Mars or the moon. All of this excitement has academia and research institutes doubling down on their efforts to anticipate the latest advances, which in turn are attracting a host of young engineers, innovators and makers.

In 2004, Behrokh Khoshnevis, a professor at the University of Southern California’s Viterbi School of Engineering, invented what he called contour crafting. Now a private business, Contour Crafting Corporation (CC Corp) claims to be able to build specially designed homes and infrastructure, and they even collaborate with NASA on several programs. In April of 2017, researchers at MIT — who are pushing the boundaries of the technology — announced they’ve developed a technique that can raise the structures of buildings more quickly than ever. In just 14 hours, a robot constructed a dome-like structure 50’in diameter and 12’high. At the Design Miami/ 2018 event, a group from MIT’s Self-Assembly Lab is even displaying a 3D printed light. A Silicon Valley startup called Cazza Construction Technologies that wants to disrupt the construction industry creates 3D printed buildings using robots, relocated to Dubai as part of the country’s accelerator program. Amazingly, Dubai has a goal to have 3D-printed buildings make up 25% of the city by 2030.

One of the more astounding developments along this front is the establishment of the Engineered Living Materials (ELM) program by the Defense Advanced Research Projects Agency (DARPA). The program is seeking to infuse living cellular systems into structural features, potentially enabling them to “heal” themselves, reproduce and self-organize. This is particularly promising not only for military uses such as self-repairing tanks and planes, but also for constructing sustainable buildings in disaster areas, remote locations and the developing world.

The Future of 3D Printing

Not only are these innovations being pushed by young startup companies looking to make create a new market in the construction industry, but 3D printing is also blowing up on college campuses across the United States. This influx of young talent into the industry is exactly what’s needed to produce huge technological strides. This past summer, students at Virginia Tech created a new way to produce complex, multimaterial products. This is a promising step in the direction of being able to 3D print all the components of a building from a single machine — electrical, plumbing, exteriors and so on. Moving beyond higher education, some high schools and middle schools are beginning to offer summer camps focused on 3D printing principles and manufacturing technologies that are attracting international attention for their forward thinking.

While still a relatively new technology, 3D printing will only continue to evolve as more companies establish partnerships with both government and educational institutions. At the rate things are currently progressing, even the older generations among us may live to experience the day-to-day advantages and wonders of a 3D-printed world.