In 2008, I started as a lab technician. In my first four years in the position, I worked together with the lab manager and was able to learn all the basics of the lab. I built and tested test specimens using our Instron machine and Partner Software. I took the ISO 17025 05 class and became trained in all the ASTMs and ACs that the lab wanted to be accredited. I took a week course to learn how to use AutoCAD program, also increased my knowledge with other software programs like Microsoft Office. In 2011 our previous lab manager got promoted to a different role, and I was given the opportunity to take over the lab as Lab Manager, I knew the responsibilities and knew that our goal was to obtain the accreditation for the lab, so I worked hard, and we got the accreditation the same year. My 14 years’ experience in the R&D department has been an excellent education, teaching me what I need to know for supporting both our customers and our fellow employees (our engineers and other testing labs) throughout the company.

My main responsibility is to manage the workflow of the lab. I receive test requests, create test write-ups, analyze the expectations of the requester, create and manage weekly schedules, manage inventory to ensure we have all the ideal parts, materials, and fasteners required for the tests, locate mill certifications and make sure we have fasteners with acceptable Bending Yield Strengths, or Fyb.

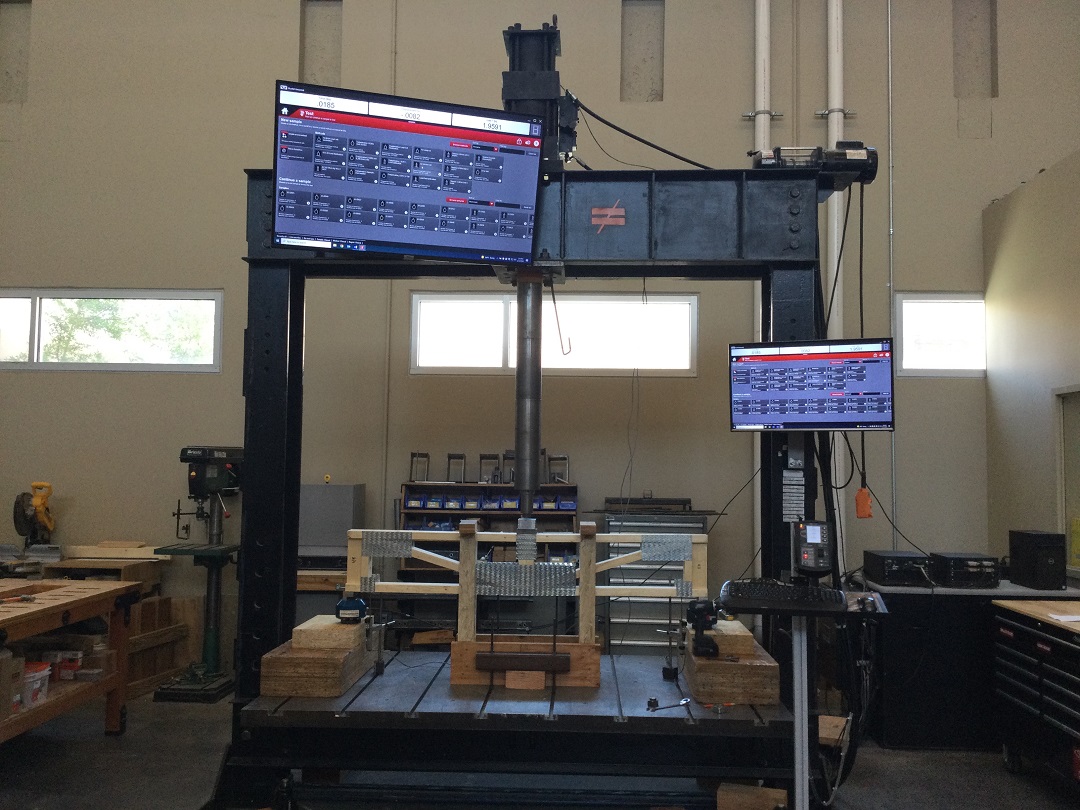

I also manage the building and testing of the test specimens. Managing data includes sending it to Engineering Services for the creation of final test reports and updating the status of our Smartsheet database. In addition, I manage the purchase of materials, parts, and equipment when needed, as well as manage internal and external audits. I also manage testing equipment with preventive maintenance and calibrations, etc.

The biggest challenge in the R&D space is knowing how to prioritize what will be most meaningful in the future. Trying to eliminate unnecessary iterations or versions before we get to the desired outcome, finding something that is desired in the field that can be manufactured to a price point that builders will use and that engineers will have confidence in.

As in other areas of the business, building and maintaining a successful R&D unit calls for excellent teamwork, with nurtured competence and excellent individual character creating mutual respect and a high-trust work environment. It means making sure to have good communication and feedback loops. Finally, it requires cultivating a growth mindset and a desire for continual improvement.

What’s unique about our lab is the fact that our team was built from little to no experience and yet was able to become accredited, to maintain our accreditation through the dedication of the entire team, and to earn the trust of our engineering team here at McKinney Texas, and that of engineers throughout the company. Also, we’ve been able to an extraordinary volume and variety of tests at our lab — for example, masonry and concrete testing, which many other testing facilities shy away from.

As for career advice for anyone interested in entering the R&D space, you have to be customer focused, creative, and positive. Take your work and safety very seriously, but don’t take yourself seriously. Show flexibility in your thinking. Obsess about a problem and know it as well as you can. Collaborate with others. Be intuitive and sensible. Seek elegant solutions. Learn from history. Learn about other existing technology. Make people’s lives easier.

Learn about the history and testing that goes on in McKinney R&D Lab on our SE blog!

Take a Tour of Our McKinney R&D Lab