Working together with our team at S&P, a Simpson Strong-Tie company since 2012, we’ve rolled out a line of asphalt pavement reinforcement grids that increase tensile strength, making roads more resistant to cracks, potholes and rutting. As a result, roads are safer, last longer and deliver greater economic value over time. The grids are easy to mill and recycle in reclaimed asphalt pavement (RAP), making them environmentally sustainable.

Twenty years of proven performance.

Our pavement reinforcement solutions have been used successfully in European pavements for years. Ideal for new projects or for resurfacing and repair, these asphalt reinforcement grids extend the service life of roads and highways, bus terminals, truck loading zones, airport runways and other pavements. In addition to projects across Europe, these grids have been installed on major highway systems throughout the world.

Setting a test standard for US roads.

Klavs Olsen, Head Engineer of European Pavement for S&P, has been closely involved with research, field installation, pavement design and product development of roadbed reinforcement solutions for two decades. Now in support of our US product launch, Klavs is leading an extensive research program conducted with the Advanced Pavement Research Center at the University of Texas at Arlington. By showing a direct correlation with improved pavement life expectancy, the program will be used to develop testing methods and design criteria for our pavement reinforcement grids.

As Klavs explains, the engineering challenges for roads in Europe and the US are similar.

“Here in the US, I see the same issues as we see in Europe. You have the same challenges as the rest of the world. So it’s really more to improve our standards and also the material we use for construction. The more we can improve our pavements, the more we gain from them. The challenge is the same.”

For pavement engineers around the world, Klavs says, the overall goal is longevity.

“Perpetual pavements are long-lasting pavements. The goal is to make them last for a very long period with minimal maintenance, without doing extensive repairs. That’s been the goal of pavement engineers all over the world.”

Unique features with powerful benefits.

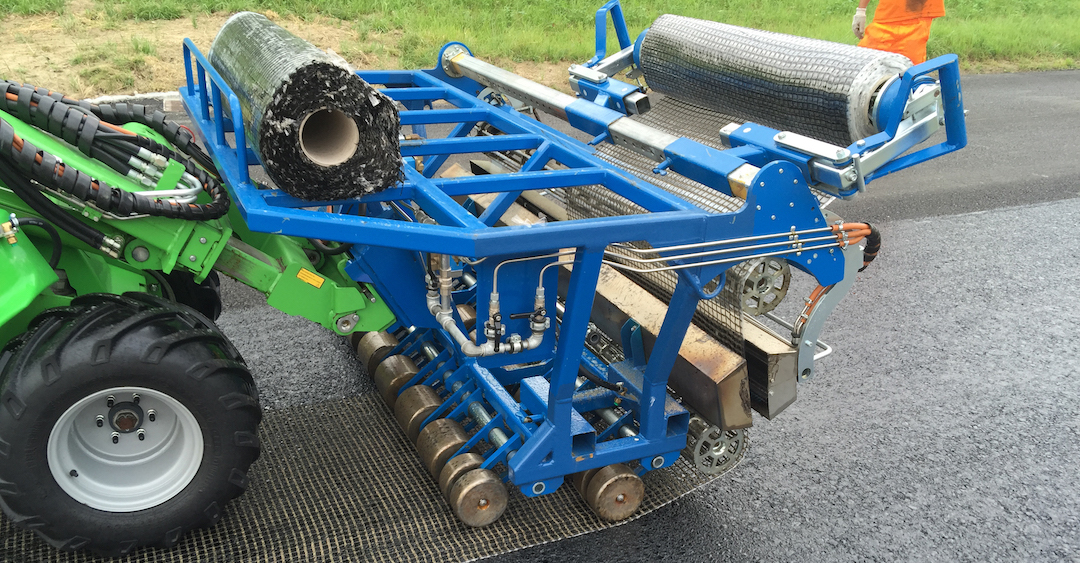

Simpson Strong-Tie asphalt pavement reinforcement grids are innovative both in engineering design and installation. Unlike other products, our solutions feature a proprietary, open grid weave that is fully saturated with bitumen. Another key difference is that our grids are heated during installation. When heated and unrolled into place by the Simpson Strong-Tie® grid installation machine, the bitumen-saturated grid adheres to the pavement and is then immediately ready to be overlaid. The open weave design will easily conform and fit roadbed curves and corners, making for a smooth installation. Additionally, the bitumen-saturated fibers form a powerful, long-lasting bond within the asphalt matrix, while the open grid design assures aggregate interlock — creating a monolithic composite pavement.

“You want an open grid because it allows aggregate interlock between asphalt courses,” Klavs says. “The unique weaving that is used allows better integration (aggregate interlock) of the mix. Our machine heats up the grid, coated with bitumen, and that’s quite unique. The bitumen-saturated grid is really important; it assures a very good bond between layers. This allows the tensile stress to be transferred to the grid.”

Three grids are available. Carbophalt™ G 200/200 is a carbon-fiber grid that provides maximum structural reinforcement and crack resistance for the most heavily trafficked pavements. Carbophalt™ G is a glass- and carbon-fiber grid for heavily trafficked pavements. Glasphalt™ G is a glass-fiber grid for a wide variety of normally trafficked pavements.

Easy to mill and recycle in future projects.

Years later, if light maintenance is required, the grids can be easily milled and recycled into reclaimed asphalt pavement (RAP) for use in new pavement projects with no decrease in performance. In addition to extending the service life of roads and highways, our grid designs make asphalt pavements recyclable and environmentally sustainable.

“Our grid is recyclable,” notes Klavs. “The fibers are easy to mill. Also, the bitumen we use is identical with an ingredient used in RAP, so it can be used in the new mix. It also adds value because the reclaimed grid is saturated with bitumen.”

Complete training and consulting support.

To help government agencies, contractors and field personnel get up to speed on asphalt reinforcement grid installation, Simpson Strong-Tie provides end-to-end product education, design consulting and operator training resources. For contractors who rent or purchase the Simpson Strong-Tie grid installation machine, we train field technicians on equipment operation and maintenance, surface preparation, application techniques, safety and jobsite troubleshooting. It’s a comprehensive solution.

“The unique thing about Simpson Strong-Tie is that we offer consulting along with our products,” says Klavs. “We help look at conditions, help decide on and establish the solution, and also the design. We are onsite to support the whole process, the whole project. We walk the extra mile for the client.”

Leading the way to safer, stronger roads.

Simpson Strong-Tie, the leader in structural engineering solutions, is committed to helping people build safer, stronger roads and highways. Our Carbophalt and Glasphalt reinforcement grids are tested, proven, economical and sustainable solutions that strengthen asphalt pavement across a wide range of applications. Proven successful on several continents, our pavement reinforcement solutions are perfect for new construction and for resurfacing and road maintenance projects throughout the US and North America.

To learn more about Simpson Strong-Tie asphalt pavement reinforcement solutions, visit strongtie.com/asphalt.