The more things change, the more they stay the same. Take framing, for instance. In November 2009, Simpson Strong-Tie Pacific Northwest Outreach Coordinator Jim Mattison penned the article Framing Hardware Dos and Don’ts for the Journal of Light Construction, outlining some of the most common framing errors as seen in the field, including notching studs and joists around anchors, using incorrect fasteners and overdriving nails with pneumatic nailing equipment.

So what’s evolved out there on the jobsite in the eight years since? “Not much,” bemoans Mattison, who says common framing mistakes still vex most of the builders he visits across the Western US. “When it comes to installing the hardware, the problems that plagued the industry in 2009 persist today, and while some of the hardware has changed in configuration and use, simple installation errors regarding use of incorrect fasteners and fastener overdrive are still happening frequently.”

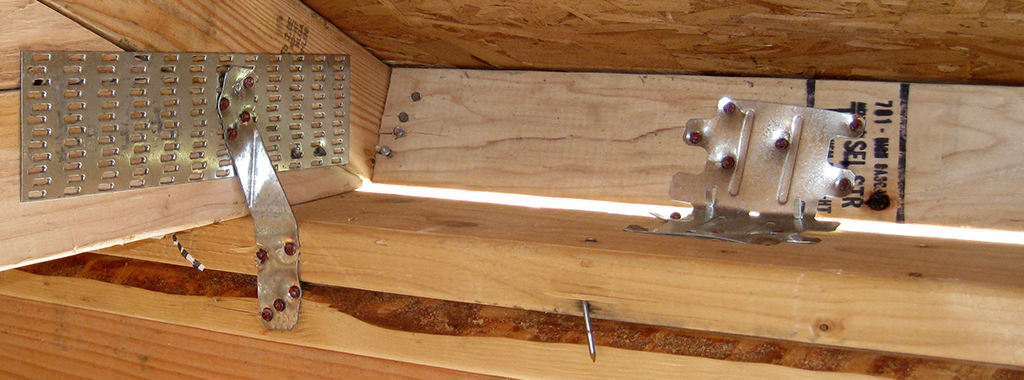

Indeed, framing contractors are still commonly using the wrong fastener to attach framing hardware, often using 1 1/2″ nails where 3″ nails are required. While the use of standard collated nails and nail size may save installers time (since they’re not switching between size and gauge), and also perhaps saves the builder a penny or two on material costs for fasteners, the results can be catastrophic.

The wrong fasteners can immediately reduce the load capacity of framing hardware – it doesn’t take a genius to figure out that thinner nails are more apt to shear and shorter ones are more apt to pull out. And what’s still worse is when fastener holes on framing hardware aren’t filled at all – yes, it happens. Construction sites are busy with a lot of pressure to complete jobs on schedule, but contractors need to show greater diligence in using the proper fasteners for framing hardware, and not simply default to whatever size nail is in their gun just to save time.

“As hardware experts, we have empathy for what goes on in the field,” Mattison says of the contractor urge to just bang out a job without switching out for proper fasteners. “It’s 42 degrees and raining and the wind is blowing and everyone is in a mad rush to keep the framing schedule, we get that.”

Simpson Strong-Tie has taken several steps to help alleviate framing contractors’ fastener frustrations in the field, including printing scale-sized pictures of the proper fasteners on cartons and packaging, or even stamped on the connector itself. The Simpson Strong-Tie Installer’s Pocket Guide features many drawings and graphics, along with straightforward directions in English and Spanish, and is small enough to fit right in a tool bag. “We also try to encourage contractors to download our product literature library on their smartphone,” Mattison says. “It’s amazing how quickly you can reference a catalog page that way to determine fastener and installation specs and instructions.”

Hardware and fastener makers can also play a more direct role in lowering the rate of framing errors by developing products that better meet jobsite conventions. Simpson Strong-Tie, for example, is exploring how to adapt hurricane ties that achieve catalog loads with common jobsite fasteners rather than requiring the use of specialty nails. “We can certainly find ways to change and improve, too, and adapt to standard field practices,” Mattison says.

Education and training – and a lot of it – will still be required to overcome the prevalence of framing errors both simple and complex in the field. Constant turnover in crew personnel figures to make that effort even more challenging.

As a case in point, Mattison helped to train two production builder concrete crews in Seattle on proper embedment of anchor installation for holdowns and then returned a week later for a follow-up. After seeing several errors immediately, he asked the builder what was happening to the trainees. “Oh those two crews you trained?” the builder answered. “We sent them to a different job.”

Proving that ultimately, overcoming framing errors might just mean repeatedly hitting the nail (and the right nail) on the head, over and over again.