The onsite installation of heavy, large-scale mass timber components can represent 30%–50% of a mass timber structure’s cost. Installation delays on a mass timber site can expose unprotected wood elements to water, causing unnecessary remediation costs. Simpson’s mass timber product development team factors the total cost of ownership in creating our latest mass timber products, putting equal consideration into the needs of the engineer and the installer. This has pushed our team to innovate and design solutions that ensure reliable, fast, efficient installation onsite — all while making zero compromises on the strength or performance of the structural connection.

Unlike the European market, where mass timber is used significantly in home and low-rise construction, here in the United States and Canada we typically apply mass timber in larger applications. Our mass timber projects are generally large-scale and have many connections. For this reason, we have focused on making the lives of the installation contractors as easy as possible. This is one of the core driving principles for developing our new HSKP™ and SCBH™ column-to-beam connection systems.

The HSKP heavy seated knife plate is one of the most innovative mass timber products to hit the market in recent years and is the first high-capacity column-to-beam connector that delivers 45°-angle screw installation without the need for angled washers or costly custom milling of the hanger. So how did we pull this off?

Our team leveraged decades of precision manufacturing to develop a 45° stamped and fully integrated screw guiding system. This innovation substantially reduces the typical cost of this connection style, removing 45° washers and decreasing the number of screws required — thereby speeding up the installation time for the contractor. And while saving 15–20 minutes on a connection installation might not seem like a big deal, imagine a typical mid– to large project with 1,000 or more connections and how much time all that installation could take.

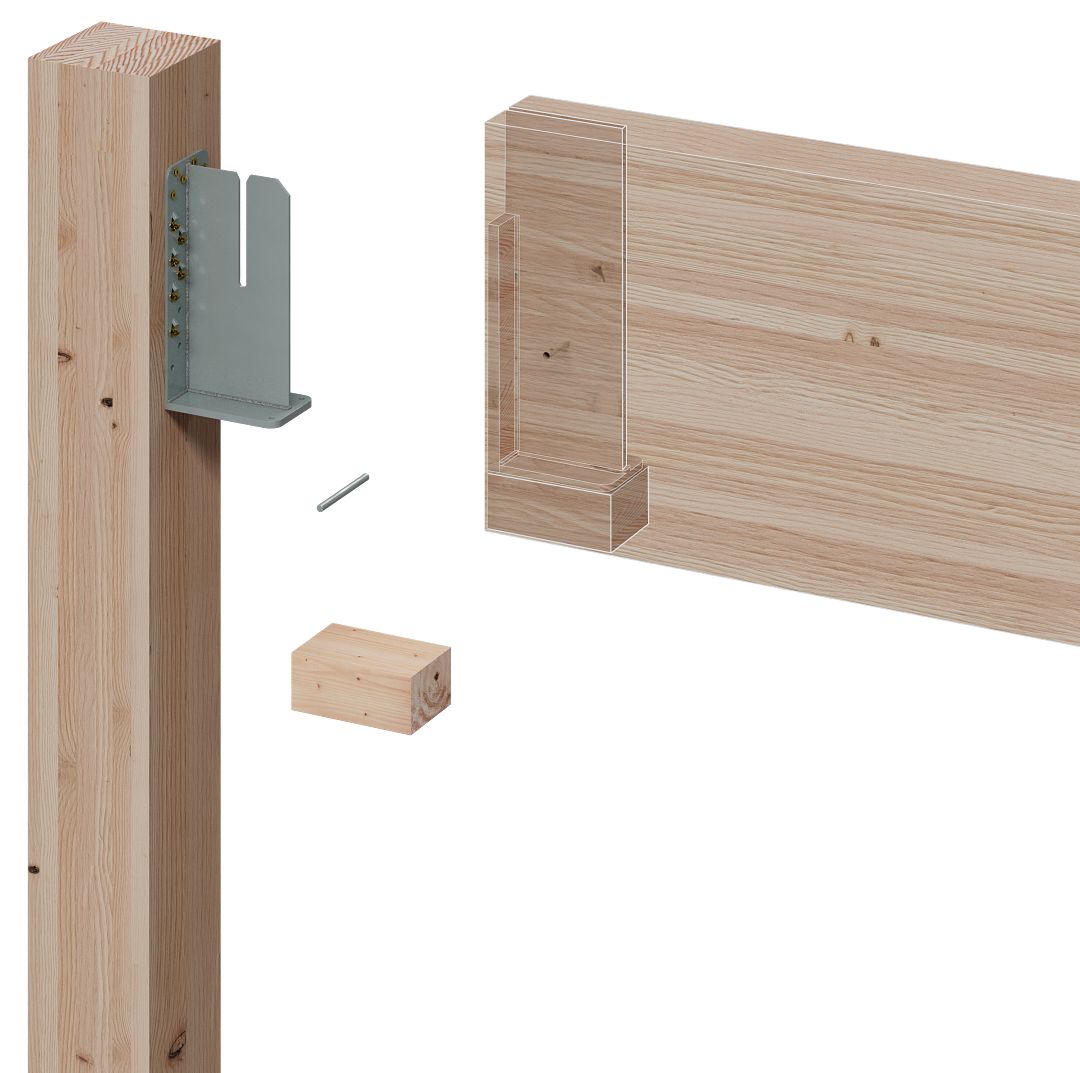

The SCBH steel concealed beam hanger takes an innovative approach to reduce installation and custom fabrication costs by allowing for wood-to-wood and steel-to-wood (welded) applications while offering installation tolerances three to five times greater than traditional concealed hanger solutions. More forgiveness on the connector means less shimming and pulling of structural members to install beams and columns to specification. And less wasted time between element placements on what are typically highly orchestrated and tightly planned erection schedules.

Keeping in mind all the project stakeholders, installers, engineers, and our domestic North American market’s unique needs, Simpson Strong-Tie will continue to promote wider adoption of mass timber construction by helping our customers reduce costs and increase productivity with smart, installation-ready solutions.