This post examines several advantages of fabric-reinforced cementitious matrix (FRCM) applications over traditional shotcrete methods in the repair and reinforcement of concrete construction.

The use of shotcrete has become quite common in repairing and strengthening structures such as tunnels, mines, silos, bridges, dams and parking garages.

But what is shotcrete, and how does it work? Basically, it involves spraying a cementitious compound over a steel grid. First, a three-dimensional rebar grid is constructed adjacent to an existing concrete, masonry, brick or dirt surface. Then a composition of cement, aggregates, water and chemical or mineral admixtures is sprayed onto the rebar.

Shotcrete itself was developed as an alternative to cast-in-place concrete. As a spray application, shotcrete has the advantage over cast-in-place concrete that it can be used to repair and strengthen irregular surfaces.

Despite its advantages over the cast-in-place method, shotcrete also has a number of disadvantages:

Labor: Installation of reinforcing steel and application of shotcrete are two separate operations. Often, both rebar and shotcrete contractors are required.

Skill level: It takes an experienced nozzle operator to spray shotcrete effectively so the reinforcing steel is fully encased by the shotcrete. Expensive training is often required.

Time: Rebar can take hours or days to install. There can be a lag time between the onsite presences of the two types of contractors.

Weight: Steel is, of course, heavy. In addition, because steel is subject to corrosion, up to three inches of concrete cover may be needed to protect the rebar from exposure to the elements. Both of these factors add weight and bulk to a structure.

Spatial impact: Shotcrete applications can be fairly thick in order to completely encase the reinforcing steel. Depending on the application, this added cover can impinge on usable space. This can result in lower ceiling heights or restricted water flow in tunnels.

The FRCM Alternative to Shotcrete

There is a thinner and lighter alternative to shotcrete. This alternative began in Europe and is gaining traction in the United States and Canada.

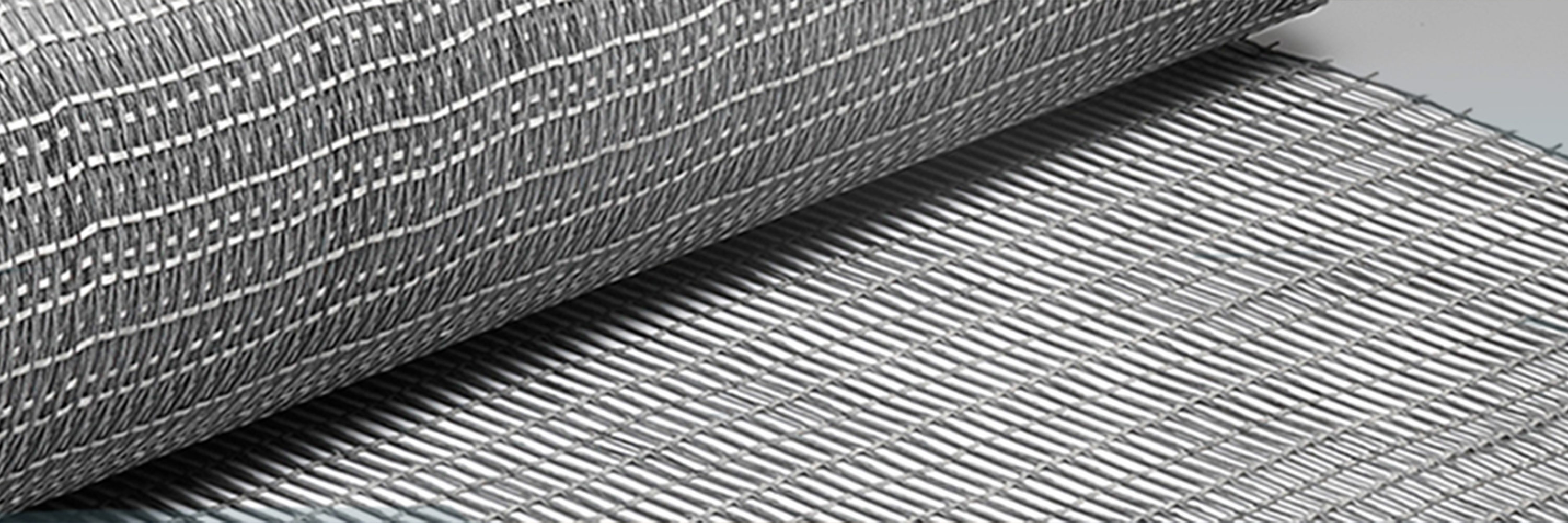

Fabric-reinforced cementitious matrix (FRCM) is conceptually similar to shotcrete. A thin layer of cementitious matrix is applied to a wet surface. A carbon-fiber reinforcing grid is added.

Placement of the grid is followed by an additional thin layer of the cementitious matrix. The surface can be finished in much the same way as concrete.

An important difference between shotcrete and FRCM is that, rather than requiring a thick and heavy mass of shotcrete to cover the reinforcing steel, FRCM starts with a thinner layer of cementitious matrix into which a portable, lightweight, carbon-fiber fabric is embedded before the final thin layer of matrix is applied. No reinforcing steel is required.

FRCM Advantages

FRCM can be applied to overhead or vertical surfaces in the same type of structures where shotcrete has been traditionally used. Here is a summary of FRCM advantages:

Strength: Carbon fiber is stiffer and stronger than steel.

Weight: FRCM is thinner and lighter and can often be a direct replacement for shotcrete and steel.

Labor: A single contractor can run an FRCM project from start to finish. FRCM does not require specially trained nozzle operators to install the system, because the carbon-fiber grid is embedded into the matrix using a trowel. By contrast, a shotcrete nozzle operator needs to be able to spray shotcrete behind the reinforcing steel so as to fully engage the rebar.

Time: FRCM is much faster to install than traditional shotcrete.

Spatial impact: The flat, two-dimensional nature of the carbon-fiber grid and the need for only a thin layer of the matrix ensure that minimal usable space is consumed.

FRCM vs. FRP

FRP (fiber-reinforced polymer) also makes use of carbon fiber. Epoxy is used to bind the system together and transfer forces from the element into the carbon fibers, whereas the FRCM system is bound together by the cementitious matrix and transfers forces from the element through the matrix into the fibers.

FRP works well for repair and strengthening of even surfaces. However, FRP systems can be challenging to install in damp areas or in areas exposed to higher temperatures.

For irregular surfaces — or for damp or hot areas — FRCM is the better choice.