Can running takeoff software and generating materials lists for new construction projects be as fun as playing a video game? The inside sales team at Jackson Lumber & Millwork sure seems to think so. Founded in 1946, Jackson is a third-generation, family-owned lumber and building materials dealer serving custom homebuilders, contractors, remodelers, and homeowners across Maine, Massachusetts, and New Hampshire.

Named by ProSales magazine as the 2014 Dealer of the Year, Jackson is committed to providing customers across New England with quality products, services, and solutions every day, relying on a dedicated staff that shares the company values and continues to be the cornerstone of the company’s success.

For years, that meant keeping pencils sharpened and project plan sets organized in order to do manual takeoffs and generate accurate lists of materials for builder customers. “Everything was done the old-school way with a physical set of plans,” says Jackson senior estimator Jason Faverty, who was on a team to identify and evaluate software to help automate takeoffs, estimating, and the creation of back-office pricing and construction documents.

Across Jackson Lumber’s four locations, customers can be pretty particular about the materials they like to use on the jobsite, and the wide variations in brand and fabrication preferences force the sales and estimating teams to wrestle with a huge catalog of SKUs in order to get the right product to the right place at the right time.

To keep up with regular customer orders and new quotes on top of that, estimators at Jackson wanted technology that was easy to learn, easy to use, and able to keep pace with business growth. “Since we were building this collection of systems, we wanted to make it future proof, as well, so if next year there is a new type of sheathing product or they come out with a new air barrier, we can easily account for that and keep rolling,” Faverty says.

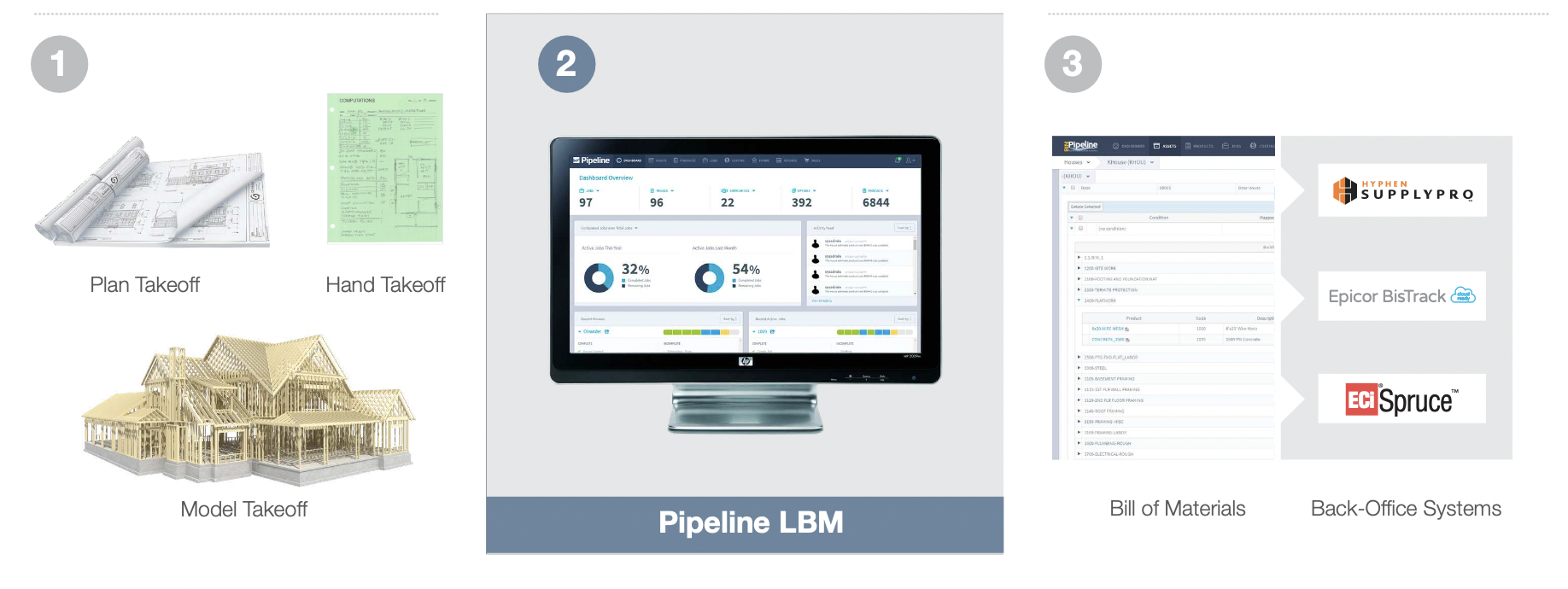

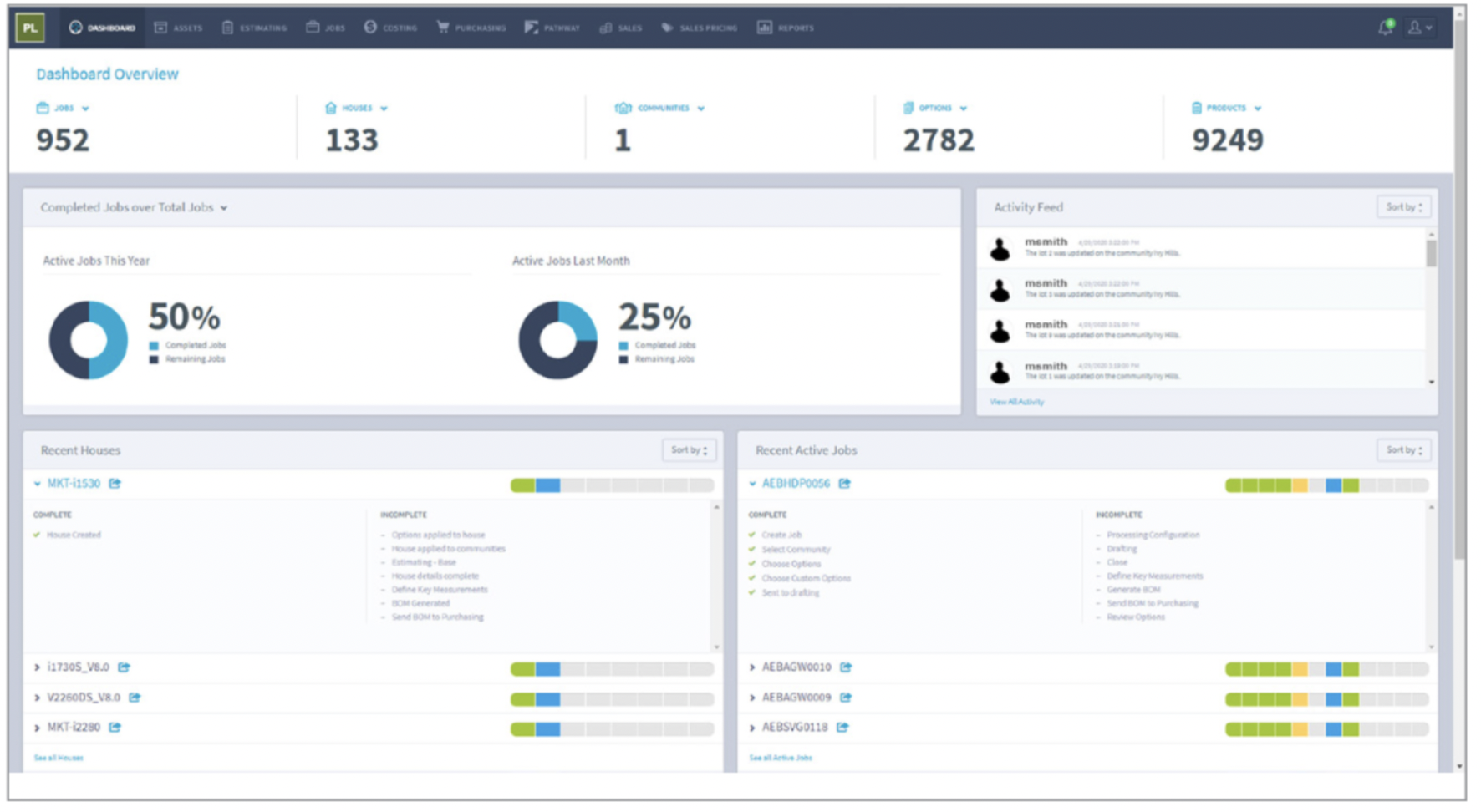

Designed to pull data from multiple applications into a single information set, the Pipeline LBM solution from Simpson Strong-Tie promised to deliver on all of Jackson Lumber and Millwork’s requirements. By bridging the gap between design and estimation for real-time, automated takeoffs, Pipeline could simplify estimates with bills of materials for each plan while managing options-driven changes and updating construction documents and back-office data.

“In New England we don’t really do tract housing,” Faverty explains. “So every building is different from every other building, even on the same street, and we had to find a way to account for those variations and still leverage a technology for making the estimating and takeoff process consistent and efficient.”

Since adopting Pipeline two years ago, the Jackson estimating team has reduced the time it takes to process takeoffs by a whopping 50 percent, and they’ve also eliminated the need for a lot of manual data entry and management between Excel sheets, PDFs, and plan documents.

That’s where the “as fun as a video game” idea comes back in. For the inside sales team, the automation of information flow and updating has been a huge lifesaver, enabling the team to stay incredibly consistent with easy-to-use options and formulas built right into the software.

“We used to send in our quotes to inside sales and they’d print out the PDF file and type up product SKUs and product quantities. So if there are 200 lines in an estimate, they have to type in 200 lines of data just to get the quote out, not to mention proofreading it for errors and typos,” Faverty says. “With Pipeline LBM, we import the estimate in Excel and every line is populated and every phase is delineated. With the click of a button, the whole estimate is loaded in, and we can get back to serving our customers without having to chew up inside sales time. They absolutely love it.”

Interested in learning more? Download the Jackson Lumber & Millwork Pipeline LBM case study here. Contact your Simpson Strong-Tie representative about finding the right LBM solution for your business.