Intuitively, it doesn’t seem that these tiny fibers could be a major component of a concrete strengthening system several times stronger than mounted steel plates.

Individually, per unit of weight, carbon fibers are twice as stiff as steel and five times as strong. But that’s just the beginning.

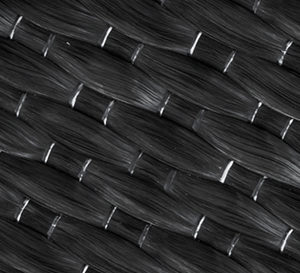

CFRP Fabric

The magic really takes off when carbon fibers are woven together to form a fabric that can ship either in a roll or as separate sheets.

By itself, carbon-fiber fabric is not especially useful. The fabric becomes useful when it’s impregnated with an epoxy resin and adhered to a surface. In combination, the fabric and resin are referred to as a composite.

After the epoxy cures, anything that the composite adheres to becomes stronger.

Carbon-Fiber-Reinforced Polymer Applications

The composite has many applications in which a combination of low weight, low spatial impact and high strength is desirable.

One of the most popular uses of carbon fiber is in road bike frames. A carbon-fiber bike has been on the podium in the last several Tour de France races.

In competitive road bike racing, every ounce counts. At the same time, a bike frame has to withstand the weight of an adult human being working at maximum physical capacity and moving at high speeds over rough street surfaces.

Commercial and Industrial Uses of CFRP

In March of 2013, the American Concrete Institute published the ACI 562 repair code. It was the first US code that provided standard requirements for evaluating existing concrete buildings and the subsequent structural repair, rehabilitation and strengthening of those buildings.

If a structure passes an unstrengthened load combination check that’s specified in the ACI 562 code, then CFRP may be considered as a strengthening option.

Carbon-fiber-reinforced polymer is often applied to structures when one or more of the following factors are present:

- Durability problems due to poor or inappropriate construction materials

- Inadequate design or construction

- Increased loading requirements due to code or use changes

- Increased life-span requirements made on aging infrastructure

- Exceptional or accidental loading

- Seismic retrofit

- Blast mitigation

The carbon-fiber fabric is saturated with an epoxy resin and then adhered to a surface. For commercial and industrial strengthening applications, especially those involving concrete structures, the surface first needs to be prepared and possibly repaired.

Commercial and industrial applications may include bridges, piers, silos, tanks or pipes.

Simpson Strong-Tie® Composite Strengthening Systems™

Learn more about applications, system solutions, fabric and epoxy types, installation and more at the Strong-Tie website.